A small locomotive criticized for its low traction power in N scale, yet also unique and iconic: the BB 900 from Hobby66. Let’s give it a little digital & sound makeover.

Sound installation, But How?

Digitizing locomotives, especially in N scale, always presents its set of challenges, but when tackling the BB 900, we reach a higher level. This locomotive, with its compact design and already full interior, leaves little room for modifications.

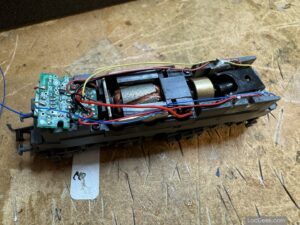

The heart of the problem: a sizable old-fashioned motor. This old-school design choice significantly limits the available space for any modifications, especially the addition of a sound system.

The BB900’s electronic board has also often been criticized on specialized forums, rightly so. Its layout makes it nearly impossible to insert a NEM651 decoder without risking damage to the light wires, thus requiring the board to be unscrewed for a simple basic decoder installation. However, once the board is removed, we find enough space in height and width to accommodate a standard-size decoder, bringing a glimmer of hope to this complex project.

The Ideal Solution: The Zimo MS500

In an ideal world, replacing the traditional motor with a miniature brushless model would have been the perfect solution. This change would have allowed for better rolling while freeing up crucial space for the installation of a speaker. However, given the unknown motor model and the complexity of the gearing, I chose not to intervene on the motor block, favoring a less invasive approach but requiring great creativity.

The Zimo MS500 decoder emerged as the only viable option (detailed in this article). Although the combination of a small decoder with a SUSI interface and a SUSI sound module was considered, the cumulative height might have interfered with the non-motorized bogie. Opting for the MS500, by foregoing direct soldering to keep the NEM socket, seemed to be the perfect compromise, aligning the necessary dimensions without requiring major modifications to the board.

Other Solutions

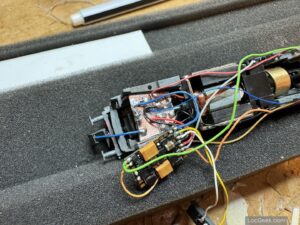

The limited space also influenced the choice of speaker. A 16x9mm model without a resonance box was selected, knowing that this would compromise sound quality, especially in the bass. Nevertheless, this setup avoids any blocking of the motorized bogie and perfectly fits the available space.

The addition of capacitors was essential to smooth out micro-cuts and prevent sound crackling and light flickering. With limited space, I opted for two 470uF SMD capacitors each, offering a total capacity close to 1000uF, in accordance with the MS500’s specifications. We’re not talking about a real “stay alive” that lasts several seconds, but precious milliseconds.

The wiring required special attention, given the limited space and the presence of the motor rotor. The use of lacquered copper wires, glued as close to the roof as possible, emerged as the only viable solution to avoid any interference with the locomotive’s operation.

Compromises were necessary. Some ideas, like adding lighting in the driver’s cabins, had to be abandoned. Priority was given to a functional installation, favoring sound and flicker-free lighting, thanks to a neat connection of the lights to the positive pole of the decoder and the judicious use of capacitors.

The Sound of a BB 8100

Unfortunately, there’s no BB 900 sound project at Zimo. So, I opted for the quite recent high-definition 16-bit project intended for the BB 8100. It does come at a cost (18 Swiss Francs), but it’s normal to compensate the few passionate experts who create these sound projects for locomotives that are not always widely sold in modeling.

Pictures of the conversion

Conclusion

In conclusion, digitizing and installing sound on the BB900 turned out to be a fine but feasible project. It doesn’t solve the problem of the locomotive’s low weight or its lack of a second motorized bogie; but it makes it a beautiful little machine that purrs. See video at the top.